Introduction

The Gen 4 pickleball paddles is here — and it’s reshaping expectations across the industry. New foam-core technologies, seamless carbon construction, and thermoforming are redefining what performance paddles should feel like.

But for brands looking to stand out in a saturated market, choosing the right OEM partner is more important than ever.

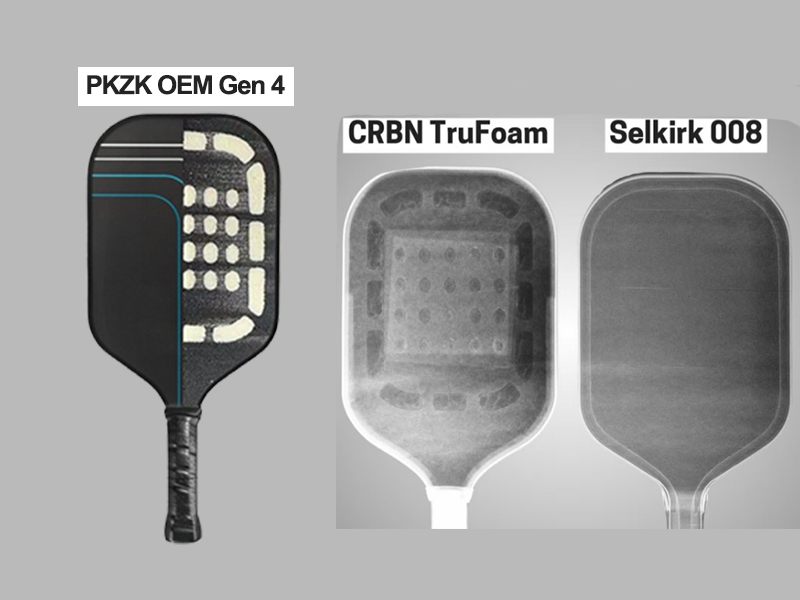

At PKZK, we’re not just pickleball paddle manufacturer — we’re the OEM supplier behind high-performance Gen 4 paddles for brands worldwide. We offer factory-direct production, full customization, and advanced construction that goes toe-to-toe with top-tier consumer brands like CRBN TruFoam and Selkirk Project 008.

In this guide, we compare all three — and show you why PKZK gives your brand the winning edge.

What Is Gen 4 in Pickleball Paddles?

“Gen 4” refers to the latest generation of pickleball paddle construction, defined by:

- A solid foam core replacing traditional honeycomb

- Thermoformed edges and surface for seamless durability

- Raw carbon fiber faces for control, spin, and power

- A focus on eliminating dead zones and edge delamination

Gen 4 paddles aim to solve the limitations of past paddle generations — making them more consistent, powerful, and long-lasting.

PKZK vs Selkirk LAB 008 vs CRBN TruFoam: What’s Really Inside?

CRBN and Selkirk dominate the headlines in Gen 4 pickleball paddle design. But behind the scenes, more and more emerging and competing paddle brands are turning to one factory to outperform them — PKZK.

As a dedicated OEM manufacturer, PKZK doesn’t just follow the Gen 4 trend — we engineer it better. With fully customizable, high-performance paddles built using advanced foam-core injection, seamless thermoforming, and optional cold press, we empower our partners to launch products that challenge — and beat — top-tier names like CRBN and Selkirk.

Here’s how they truly compare:

| Feature | PKZK Gen 4.0 | Selkirk LAB 008 | CRBN TruFoam |

| Core Material | Epoxy pressurized foam | Static PureFoam (no epoxy) | Punched foam core |

| Foam Fill | Fully filled, solid core | Hollow center, no full fill | Partially filled with holes |

| Power Output | ⭐⭐⭐⭐⭐ | ⭐⭐⭐ | ⭐⭐⭐⭐ |

| Rebound Feel | Consistent and powerful | Inconsistent, hollow | Finesse, low pop |

| Vibration Control | Excellent | Moderate | Moderate |

| OEM Friendly? | ✅ Full customization | ❌ Brand only | ❌ Brand only |

Selkirk LABS Project 008: Foam Core, But Hollow

Selkirk’s LAB 008 looks premium with its carbon face and thermoformed body. But inside, the “PureFoam” core isn’t filled with epoxy and lacks internal expansion.

This creates a hollow feeling, with:

- Reduced power during drives and volleys

- Poor energy return

- More fatigue over long play sessions

For players demanding power, LAB 008 often underdelivers — and competitors know it.

CRBN TruFoam: Hollow Holes, Not True Impact

CRBN introduced “TruFoam” to boost core consistency, using holes inside a non-epoxy foam. But without epoxy infusion or foam expansion, the paddle:

- Prioritizes light feel over power

- Lacks punch on smashes and overheads

- Shows edge inconsistency

It’s built for finesse, not force — leaving a clear performance gap for brands who want to target competitive players.nesse, not force — a disadvantage for intermediate to advanced players who demand more pop.

PKZK Gen 4.0: Solid-Core Foam Engineering That Delivers Real Power

At PKZK, our Gen 4 paddles are built using epoxy foam injection + high heat thermoforming, which fills every inch of the paddle core with solid, pressurized foam.

This results in:

- Consistent core density from edge to edge

- Superior energy transfer with each strike

- Pro-level rebound and stability

- Zero hollow spots or vibration drop-off

- Elite-level power output without sacrificing feel

You get a paddle that feels solid, swings hard, and holds up match after match — all ready to be OEM branded under your company name.

Hot Press vs Cold Press: Your Choice, Your Control

At PKZK, we offer both manufacturing methods:

Thermoforming (Hot Press)

- Seamless paddle body

- Higher stiffness and power

- Ideal for advanced or pro-level play

Cold Press Foam Core

- Lightweight design

- Smooth touch and forgiveness

- Excellent for intermediate or entry-level markets

This flexibility allows you to build a tiered product line — something most competitors can’t offer.

Why PKZK Wins the Gen 4 Paddle War for OEM Buyers

- We Manufacture — You Brand

We don’t sell direct to consumers. Our success comes from your success as a brand owner. - Performance That Competes with CRBN & Selkirk

Our paddles match or exceed top-tier brands in durability, feel, and power. - Faster Time to Market

With existing Gen 4 molds and tech, you can launch your line faster — without compromising on innovation. - Factory-Direct Pricing

No middlemen. We give you cost control and better profit margins. - Flexible MOQ for Startups or Scale

Whether you’re launching your first product or your tenth, we’re ready to support you.

Conclusion: Ready to Build a Better Paddle Line? Start with Gen 4.0 and PKZK

CRBN and Selkirk built the Gen 4 hype. Now it’s your turn to build something better.

At PKZK pickllball, we give you the materials, manufacturing, and flexibility to create Gen 4 paddles that perform better — and help your brand stand out in a crowded space. Whether you’re launching your first line or improving your next-gen design, we’re ready to help you build what’s next.

If you’re ready to create a Gen 4 pickleball paddle that outperforms CRBN and Selkirk, partner with PKZK — and let’s build your competitive edge together. Contact us today to start your OEM project.

4 comments