Introduction

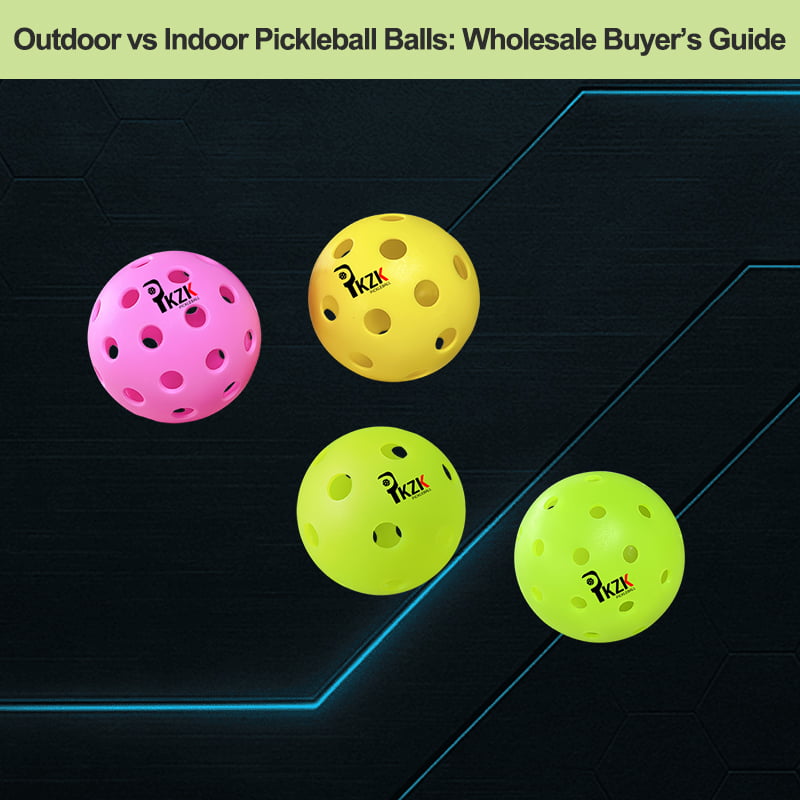

Lors de l'achat de balles de pickleball en vrac, il est important de comprendre les principales différences entre les balles de pickleball et les balles de pickleball. extérieur et intérieur Il est essentiel de connaître les différents types d'aires de jeu pour prendre la bonne décision d'achat. Chaque type est conçu pour des environnements de jeu différents, ce qui influe non seulement sur le matériau et les performances, mais aussi sur les attentes de vos clients.

Au PKZKNous ne sommes pas seulement un fournisseur de confiance de balles de pickleball, nous sommes aussi un fournisseur professionnel de balles de pickleball. fabricant de pagaies de pickleball. Notre production interne et notre contrôle de la qualité garantissent que chaque produit répond aux normes de performance attendues par les clubs, les écoles et les détaillants du monde entier.

Nous fournissons :

- Billes moulées par injection - Rentable pour les programmes de formation et les programmes en vrac

- Billes rotomoulées - Durable et cohérent pour les applications haut de gamme

- Boules silencieuses - Conçu pour les environnements intérieurs sensibles au bruit

- Pagaies de pickleball personnalisées - Solutions OEM et personnalisées disponibles dans différentes formes, noyaux et matériaux de surface

Que vous soyez un détaillant de sport, un club, une école ou une ligue de loisirs, ce guide vous aidera à comprendre les distinctions pratiques entre les balles de pickleball d'intérieur et d'extérieur, afin que vous puissiez sélectionner en toute confiance les bons produits pour votre marché.

Pourquoi la méthode de fabrication est-elle importante pour les acheteurs en gros ?

Lorsque vous achetez des balles de pickleball en vrac, la façon dont elles sont fabriquées a un impact direct sur la qualité du produit, la satisfaction du client et les commandes répétées. Il existe deux méthodes principales de fabrication des balles de pickleball : moulage par injection et moulage par rotation. Chaque méthode crée un type de balle différent, tant au niveau de ses performances que de sa durée de vie.

Moulage par injection : Un budget raisonnable et des volumes importants

Les billes moulées par injection sont fabriquées en pressant du plastique fondu dans un moule pour former deux moitiés, qui sont ensuite fusionnées. Cette méthode est rapide et rentable. Elle est idéale pour les commandes importantes à bas prix.

- Couramment utilisé pour: balles d'intérieur (26 trous) et d'extérieur (40 trous)

- AvantagesLe jeu : coût réduit, production plus rapide, idéal pour la formation, les écoles ou le jeu occasionnel.

- Ce qu'il faut savoirLes coutures sont visibles tout autour de la balle ; elles peuvent s'user ou se fissurer plus rapidement en cas d'utilisation intensive.

Moulage par rotation : Sans soudure et durable

Le rotomoulage consiste à faire tourner lentement un moule rempli de résine plastique, ce qui lui permet de recouvrir uniformément l'intérieur et de former une boule d'un seul tenant et sans soudure. Ce procédé prend plus de temps mais permet d'obtenir des produits plus durables et plus cohérents.

- Couramment utilisé pour: balles de qualité supérieure pour l'extérieur ou pour les tournois

- AvantagesStructure plus solide, pas de couture, durée de vie plus longue, rebond et vol plus réguliers.

- Ce qu'il faut savoircoût unitaire plus élevé, mieux adapté aux clubs, aux détaillants et aux acheteurs de jeux de compétition

Pourquoi c'est important pour vous

Si vos acheteurs accordent de l'importance à durabilité et performancele moulage par rotation est le meilleur choix. S'ils ont besoin de des balles abordables en grandes quantitésLe moulage par injection peut être la solution idéale. Beaucoup de nos clients grossistes choisissent de stocker les deux types pour répondre aux différents besoins et budgets des clients.

Balles d'intérieur et d'extérieur - Quelle est la différence ?

Les balles de pickleball d'intérieur et d'extérieur peuvent sembler similaires, mais elles sont construites différemment pour s'adapter à leur environnement de jeu. Si vous vous approvisionnez en balles de pickleball en vrac, la compréhension de ces différences vous aidera à choisir les bons produits pour vos clients, qu'il s'agisse d'écoles, de clubs ou de revendeurs.

1. Nombre et taille des trous

L'une des différences les plus notables entre les balles de pickleball d'intérieur et d'extérieur est la taille de la balle. le nombre et la taille des trous.

- Ballons d'intérieur avoir 26 trous plus grands. Ces ouvertures plus larges permettent à la balle de se sentir plus léger et plus doux pendant le jeu. Il se déplace plus lentement dans l'air, ce qui le rend plus facile à contrôler, en particulier dans les environnements intérieurs où il n'y a pas de vent.

- Boules d'extérieur ont généralement 40 trous plus petits. La taille réduite permet à la balle de couper à travers le vent extérieur et de maintenir la pression sur le sol. un vol plus droit et plus stable. Ils sont donc mieux adaptés aux conditions extérieures imprévisibles.

Bien que les diamètres exacts des trous puissent varier légèrement d'une marque à l'autre, la règle générale est la suivante :

- Intérieur = moins de trous, plus grands → sensation plus douce et mieux maîtrisée

- Extérieur = plus de trous, plus petits → vol plus rapide et plus résistant au vent

Chez PKZK, nous proposons des options de 26 trous et de 40 trous dans plusieurs types de fabrication, afin que vous puissiez fournir à vos clients la solution la mieux adaptée à leur environnement de jeu.

2. Taille et poids standard

Les ballons d'intérieur et d'extérieur sont conçus pour répondre aux USAPA/IFP normes :

| Propriété | Gamme de spécifications |

|---|---|

| Diamètre | 2,87 - 2,97 pouces (73 - 75 mm) |

| Poids | 0,78 - 0,935 oz (22,1 - 26,5 g) |

| Hauteur du rebond | 30 - 34 pouces à une hauteur de 78 pouces |

| Dureté | Échelle Shore D : 40 - 50 préférée |

Chez PKZK, tous nos ballons d'intérieur et d'extérieur sont ingénierie de précision pour répondre à ces spécifications. Qu'elles soient fabriquées par injection ou par rotomoulage, nos balles sont soumises à des contrôles de qualité stricts afin de garantir la cohérence de la taille, du poids et de l'alignement des trous.

3. Durabilité des matériaux et des surfaces

- Ballons d'intérieur utilisent des plastiques légèrement plus souples (tels que le PP ou le TPE souple), qui offrent un rebond plus faible et un son plus silencieux - idéal pour les sols en bois ou en caoutchouc des salles de sport.

- Boules d'extérieur sont fabriqués avec des plastiques plus durs (comme le PE ou le TPE rigide), ce qui leur permet de durer plus longtemps sur les terrains accidentés et de résister aux fissures dues au soleil ou au froid.

4. Différences de performance

| Fonctionnalité | Balles d'intérieur (26 trous) | Boules d'extérieur (40 trous) |

|---|---|---|

| Nombre de trous | 26 grands trous | 40 petits trous |

| Diamètre du trou | 7-8 mm (plus grand) | 5-6,5 mm (plus petit) |

| Matériau | Plastique plus souple | Plastique plus dur |

| Durabilité | Modéré | Plus élevé - résistant aux fissures |

| Rebondir | Rebond plus faible, sensation plus douce | Rebond plus important, sensation plus ferme |

| Stabilité des vols | Moins affecté par le vent (à l'intérieur) | Conçu pour résister au vent (à l'extérieur) |

| Meilleure utilisation | Gymnases, ligues intérieures, jeux tranquilles | Clubs de plein air, courts publics |

PKZK Tip :

Lorsque vous choisissez des balles de pickleball pour votre stock ou vos canaux de distribution, tenez compte à la fois de la qualité des balles et de leur prix. environnement ludique et de vos clients attentes en matière de performance:

- Pour installations intérieures tels que les gymnases, les écoles ou les centres de loisirs, nous recommandons Boules intérieures à 26 trous. Les trous plus grands réduisent la résistance à l'air, offrant un vol de balle plus lent et plus contrôlé - idéal pour les débutants, les joueurs seniors, ou les environnements où un rebond plus doux et un bruit plus faible sont importants.

- Pour courts extérieursPour les parcs publics, les clubs de sport ou les sites de tournois, choisissez Boules d'extérieur à 40 trous. Elles sont conçues pour résister au vent et aux surfaces rugueuses, offrant un rebond constant et une durabilité à long terme.

Chez PKZK, nous proposons des options de 26 trous et de 40 trous dans plusieurs types de fabrication, afin que vous puissiez fournir à vos clients la solution la mieux adaptée à leur environnement de jeu.

Conclusion : Les bonnes balles de Pickleball commencent avec le bon fournisseur

Alors que le pickleball continue de se développer dans le monde entier, les acheteurs en gros doivent proposer plus qu'un simple équipement de base. Comprendre les différences entre balles de pickleball pour l'intérieur et l'extérieur, leur les méthodes de fabricationPour stocker les bons produits et servir vos clients en toute confiance, il est essentiel de connaître les caractéristiques des produits et leurs performances dans différents contextes.

Au PKZK PickleballNous fabriquons et fournissons une gamme complète de balles de pickleball adaptées à différents environnements, besoins des joueurs et niveaux de budget :

- Billes moulées par injection - Idéal pour les achats en grande quantité et rentables

- Billes rotomoulées - Option Premium pour les tournois et les jeux compétitifs

- Boules silencieuses - Parfait pour les installations intérieures soumises à des restrictions sonores

Nous prenons en charge l'impression de logos personnalisés, des MOQ flexibles, des emballages de marque privée et une livraison rapide dans le monde entier, ce qui facilite l'expansion de votre gamme de produits de pickleball en toute confiance.

Que ce soit pour un grand distributeur, une marque de sport ou un nouveau programme de pickleball, notre équipe est là pour vous aider. Contacter l'équipe de vente PKZK Aujourd'hui.